How litho printing Delivers Sharp and Vivid Prints

Wiki Article

A Comprehensive Guide to Understanding Litho Printing Methods

The globe of litho printing, a method originating from the late 18th century, is a fascinating blend of background, advancement, scientific research and art. Remain with us as we journey into the fascinating realm of litho printing.The Historical Development of Litho Printing

The historical trajectory of litho printing, a critical innovation in the world of communication, is an exciting story of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this technique was initially a cost-effective technique of releasing theatrical works. Lithography, obtained from the Greek words for 'rock' and 'to write', utilized a smooth stone surface to transfer pictures onto paper. The process progressed with the development of the rotating press, which substantially increased productivity (litho printing). In the 20th century, the development of balanced out lithography reinvented the market, enabling automation of premium prints. Each stage of litho printing's development showcases humankind's ruthless pursuit of effectiveness and top quality in aesthetic communication.Decoding the Science Behind Litho Printing Inks

Progressing in the exploration of litho printing techniques, the emphasis now changes to the scientific research behind litho printing inks. The composition of these inks, their drying process, and shade mixing methods form the foundation of this intricate art kind. Comprehending these elements is crucial to understanding the craft and achieving the preferred print outcomes.Structure of Litho Inks

In lithographic printing, the essential function of litho inks can not be overstated. Pigments, the color-providing components, are carefully ground fragments put on hold in the automobile, a liquid that carries the pigment onto the printing surface. Each part plays a crucial part in the final print's top quality, making the precise formula of litho inks a complex scientific research.Ink Drying Process

From the make-up of litho inks, focus transforms to the fascinating process of ink drying out. The drying procedure is vital, as it influences the last print's top quality and longevity. Two main techniques are made use of in litho printing: oxidative drying and absorption. Oxidative drying involves the ink reacting with oxygen in the air to form a tough, dry film. This technique offers a resilient coating, however can be slower contrasted to absorption. Absorption, on the various other hand, entails the ink permeating right into the paper fibers, which is a much faster procedure but can result in less dynamic shades. The selection in between these approaches is dependent upon variables such as print rate demands, the paper type used, and the preferred surface.Color Combining Methods

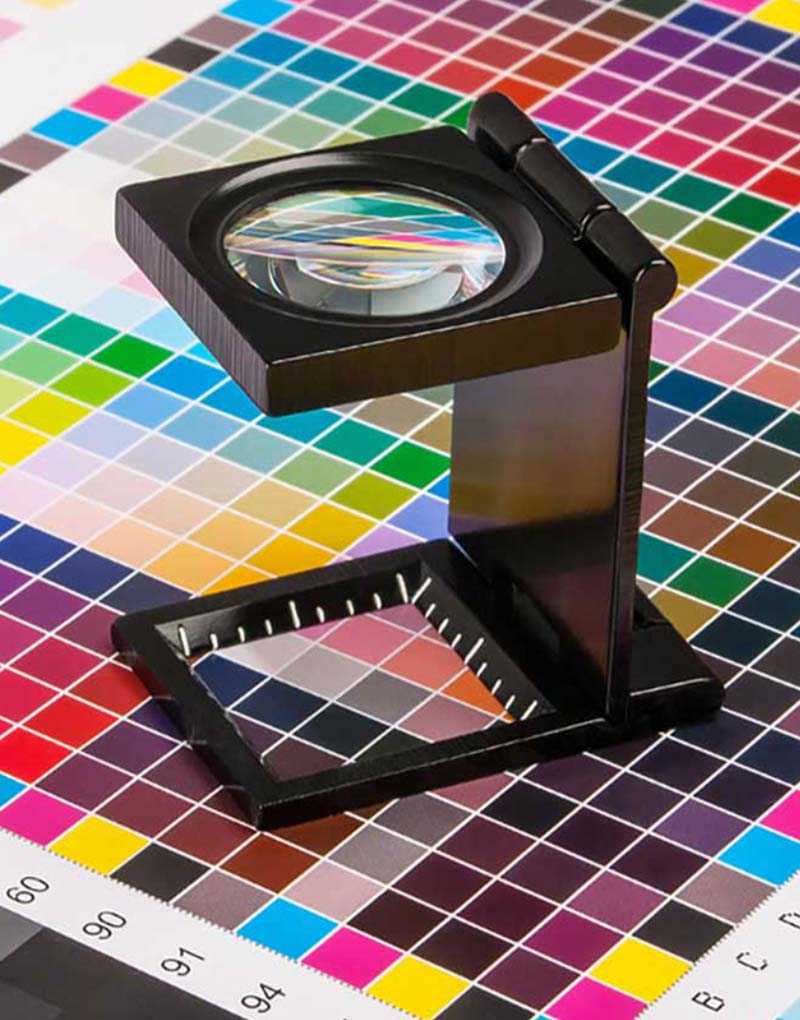

While the drying process plays a vital function in litho printing, the science of shade blending methods holds equivalent relevance. This is a complex procedure that includes the careful blending of primary shades: cyan, magenta, and yellow, in varying percentages to accomplish a broad selection of colors. The addition of black ink, called 'essential', aids in controling the intensity and deepness of the colors. The science behind litho printing inks additionally takes into consideration the transparency of the ink, which impacts how shades overlay and mix. To accomplish an effective shade mix, print professionals have to likewise recognize the ins and outs of ink habits, shade theory, and the physical buildings of the substratum on which the ink is used.The Art and Layout Components in Litho Printing

Litho printing breathes life into art and style via its distinct aspects. The procedure entails developing an image on a lithographic sedimentary rock plate or metal plate with a smooth surface area. The picture is then printed onto a tool, normally paper, by transferring the ink from the plate. What collections litho publishing apart is its ability to replicate detailed designs with high integrity, making the result almost identical to the original artwork. This is attained via making use of different line methods such as stippling, cross-hatching, and hatching, which enable a variety of tonal results. Litho printing redirected here fits a range of colors, allowing artists to develop lively and vibrant prints. This combination of precision and convenience makes litho printing a favored selection for many artists and designers.Modern Applications of Litho Printing Methods

Litho printing methods have actually located comprehensive usage in the contemporary business field. Its impact and value remain to grow with the development of new technologies and innovations in the area. This area will discover these contemporary applications and the transformative role they play in the printing industry.

Commercial Litho Printing Utilizes

In today's electronic age, one might question the significance of standard printing approaches. Litho printing stays an important part of the commercial field. High-volume printing tasks, such as the production of books, papers, and packaging, rely on litho printing for its capacity to deliver superior picture quality and price efficiency. The procedure, which involves moving a tattooed photo from a plate onto a rubber blanket and after that to the printing surface area, uses unparalleled uniformity. This makes it suitable for tasks needing a huge print run. Litho printing additionally gives a wide color range, superior to that of electronic printing. This makes it the go-to choice for jobs that require dynamic, top notch color recreation.Advancements in Litho Printing

Pushing the borders of typical methods, contemporary advancements have actually fueled a host of advancements in litho printing. One popular growth is digital litho printing, which integrates the virtues of digital modern technology with litho's high-quality result. These technologies emphasize the long-lasting importance of litho printing in the contemporary globe.Checking out the Process of Litho Printing: Detailed

Difficulties and Solutions in Contemporary Litho Printing

Despite the precision and custom that litho printing proudly supports, it is not without its collection of contemporary obstacles. Digital litho printing allows for cost-effective short runs and simple personalization, attending to the concern of variable information. Hence, while there are difficulties, the litho printing market is proactively adapting to satisfy them head-on, view guaranteeing its importance in the future.

Conclusion

To conclude, litho printing, with its rich background and clinical complexities, holds a substantial location in the print sector. As the overview reveals, it's a synthesis of art and technology, with modern-day improvements guaranteeing its relevance. Nevertheless, the industry deals with obstacles that call for innovative services, with a concentrate on automation and sustainability. The future of litho printing rests on its capacity to adjust to these transforming demands, verifying its long-lasting worth in a developing market.

Report this wiki page